What is the current status of the use of degradation materials in the field of adhesive tapes? Can they replace traditional adhesive tapes? China's new "Plastic Restriction Order" issued in 2020 requires the use of non-degradable plastic tape to be banned by the end of 2025, and the promotion of national policy, coupled with the demand for environmentally friendly tape packaging for some international businesses, has made the research and development of degradable environmental tape a hot topic.

Status of biodegradable environmental tape

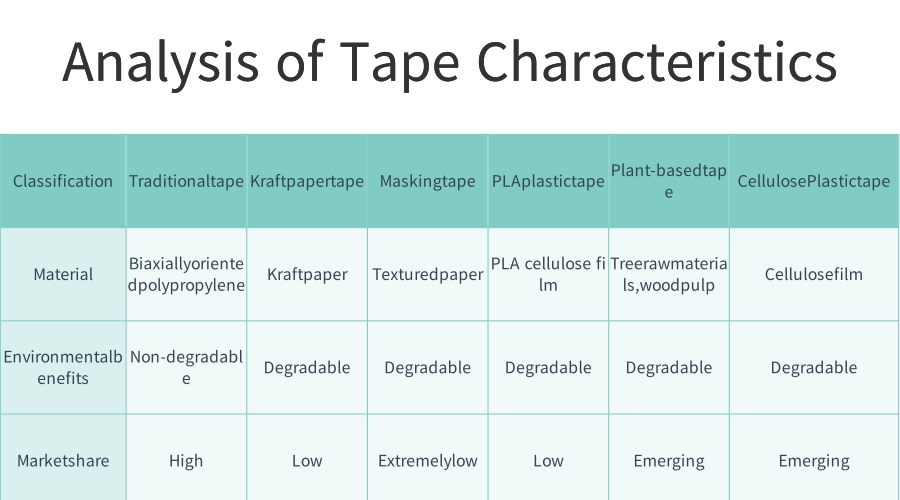

The tape, consisting of five parts: base film, adhesive, primer, base treatment agent, and the isolation layer. According to the base material, it can be divided into BOPP tape, cloth-based tape, kraft paper hundred tape, paper tape, PET tape, PVC tape, PE foam tape, and so on. At present, the industry's environmental tapes are mainly kraft paper tape, paper tape, biodegradable tape, plant-based tape, and cellulose tape.

Kraft paper tape was the first to appear, but the kraft paper substrate itself is poor toughness, breaking force can not meet the standard requirements, modified and qualified kraft paper tape is more expensive.

Biodegradable tape with PLA as the base material, the current low production of raw materials, high cost, resulting in expensive costs, and PLA material poor breaking force, performance is generally not better than the traditional BOPP material, the need for its modification research.

Plant-based tape base material using cellulose derived from trees, raw materials, wood pulp cellulose, high strength, but the raw material is expensive, the production process is complex, resulting in relatively high costs; cellulose tape is also based on cellulose, the production process is simplified, thereby reducing production costs.

Currently, on the market using mostly traditional BOPP tape, environmental tape use is less. Kraft and PLA tapes are used in the market, but the proportion of applications is very small.

Plant-based tape and cellulose tape is a new type of environmentally friendly tape on the market at this stage, of which foreign plant-based (cellulose) tape production process has matured, in Japan, South Korea, and the EU and other countries with strict environmental policies have been applied.

The adhesive coating process of environmentally friendly tapes needs to be improved

At this stage, China is all about the traditional BOPP coating process. Some of the environmentally friendly tapes, such as cellulose tapes, have a different cellulose base material to the plastic base material, so the coating process needs to be continuously improved to enhance the tape's initial adhesion, tackiness and other performance indicators to ensure the safety of the items being sent.

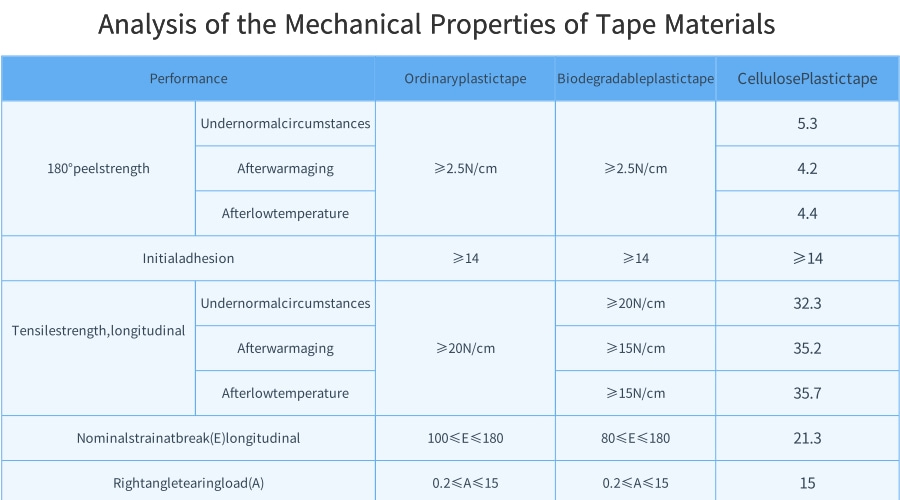

Some of the properties of environmentally friendly tapes are not up to standard

Although environmentally friendly tapes are green and non-polluting, their elongation at break values are not comparable to those of ordinary tapes. At this stage, most eco-friendly tapes are lower than traditional BOPP tapes in terms of this performance indicator.

In the case of cellulose tapes (test samples have a random type), for example, the nominal strain at break is more than 20, which is far from the standard minimum value of 80. Apart from this indicator, all other performance indicators meet the requirements of the standard, so it is expected that this indicator will likely be a focus of research for biodegradable tapes.

Preparation process of a new type of fully biodegradable plastic tape

On 4 September 2020, a team of researchers from the Institute of Physical and Chemical Sciences, Chinese Academy of Sciences, prepared a new type of fully biodegradable adhesive tape by using PLA and PBAT as raw materials, adding lubricants and nucleating agents and other additives, through the process of film formation, coating and drying, etc. The main components of the main part of this biodegradable plastic tape - the substrate layer - are PLA and PBAT, of which the mass of PBAT accounts for 50%-99%.

The cost of environmentally friendly tapes is generally higher than traditional tapes. The cost of environmentally friendly tapes is higher due to the material used. At this stage, there are two main biodegradable materials, PLA and cellulose.

Sealong Biobased commits itself to the research, production and sale of bio-based polymer material and technology export. At the same time, our company is guided by the core values of creating green value, constructing upstream and downstream industry alliance, win-win cooperation, and repaying the society. Our bags are certified with EN13434, ASTM6400, etc. 6 years of manufacturing and exporting experience in 100% biodegradable and compostable bags and resins. We hope to be your partner by providing the most favorable price and reliable quality to you.