Biodegradable plastic is a completely biodegradable material with great development potential and a very high degree of industrialization. It is easy to modify and is suitable for making all kinds of disposable film materials, such as packaging bags, shopping bags, garbage bags, and mailers bags. , Mulch film and food packaging bags and other new biodegradable plastic products. These products are not only comparable to traditional plastic products in terms of mechanics, heat resistance, stretching, etc., but more importantly, the products are non-toxic and odorless and are easily decomposed and metabolized by a variety of microorganisms in nature or enzymes in animals and plants. , And finally completely decomposed into carbon dioxide and water.

Biodegradable plastic bags on the market can be roughly divided into three categories:

-

The first category is the addition of corn starch or calcium carbonate to traditional plastic materials. Such additives can accelerate the decomposition of plastic bags into small pieces, but cannot make the plastic disappear.

-

The second type is the addition of photosensitive accelerators to traditional plastics. This plastic can also be broken into small pieces, but it is still plastic and still causes white pollution.

-

The third type is called compostable plastics in Europe and the United States. This type of plastic does not contain traditional plastics (such as polyethylene PE, polypropylene PP, polystyrene PS, polyvinyl chloride PVC), and becomes decomposed by microorganisms. Organic matter, carbon dioxide and water are truly biodegradable.

In order to ensure that compostable biodegradable plastics can really be completely degraded, the European Union, the United States, Japan, and Australia have all introduced strict certification procedures. In Taiwan, China, the Environmental Protection Agency's environmental label also provides certification for biodegradable plastics. In addition, such plastics still use additives in the manufacturing process. Therefore, during the certification process, it must also be ensured that no toxic or harmful heavy metals remain after decomposition, so as to prevent harmful substances from remaining in the soil and entering the food chain and endangering human health.

China Taiwan and international biodegradable plastics certification. The bottom left is: Environmental Protection Agency's environmental label; the rest are: International degradable (compostable) certification: BPI certification / Vincotte certification / GreenPla certification / DIN CERTCO certification.

When consumers are shopping for biodegradable plastic bags, as long as they have these certification marks, they can buy and use them with confidence.

Anhui Sealong Biobased Industry Technology Co., Ltd. has obtained the following certifications. We have been working hard to protect the environment and eliminate white pollution.

At present, the biodegradable plastics and products developed and produced by our company can not only meet the market demand in this region, but also are exported in large quantities to developed countries and regions such as Europe and America. The products are very popular in the local market and customer satisfaction is extremely high.

Biodegradable plastics are biodegradable, but the raw materials do not necessarily come from bio-based. Biobased plastics are raw materials from natural sources, but they may not be degradable. The two are often confused by the public. In addition, most people think that biodegradable plastic is PLA (polylactic acid). This is also a misunderstanding. PLA is only one of the biodegradable materials. PLA is made by polymerizing lactic acid extracted from natural grains. It is commonly used in containers, such as cold drink cups, lunch boxes, straws, etc.

Biodegradable plastic bags are mostly bio-based composite materials, such as polybutylene succinate (PBS), polybutylene succinate terephthalate (PBAT) blended with PLA and starch.

At present, the certification procedures of various countries in the world are slightly different. Generally speaking, bio compost certification is divided into four procedures:

-

Material analysis: testing volatile solids and heavy metal components.

-

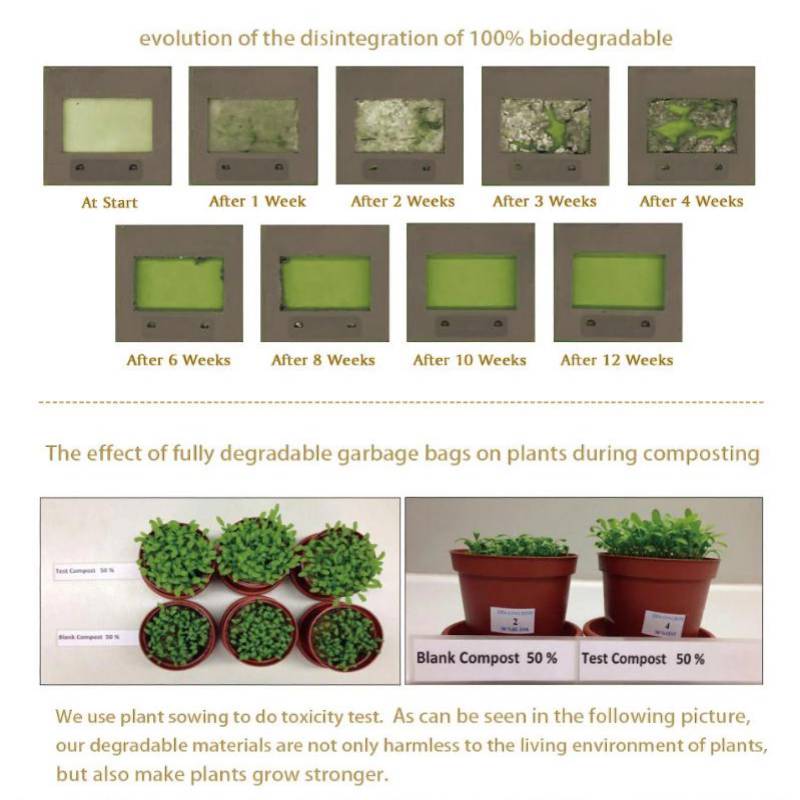

Biodegradability test under aerobic environment (temperature 56~58℃): it must reach the standard of 90% decomposition within 180 days.

-

Simulated industrial composting environment (high-temperature 60~75℃, low temperature should not be lower than 40℃, humidity is about 60~70%) cracking rate test: 90% must be cracked within 90 days.

-

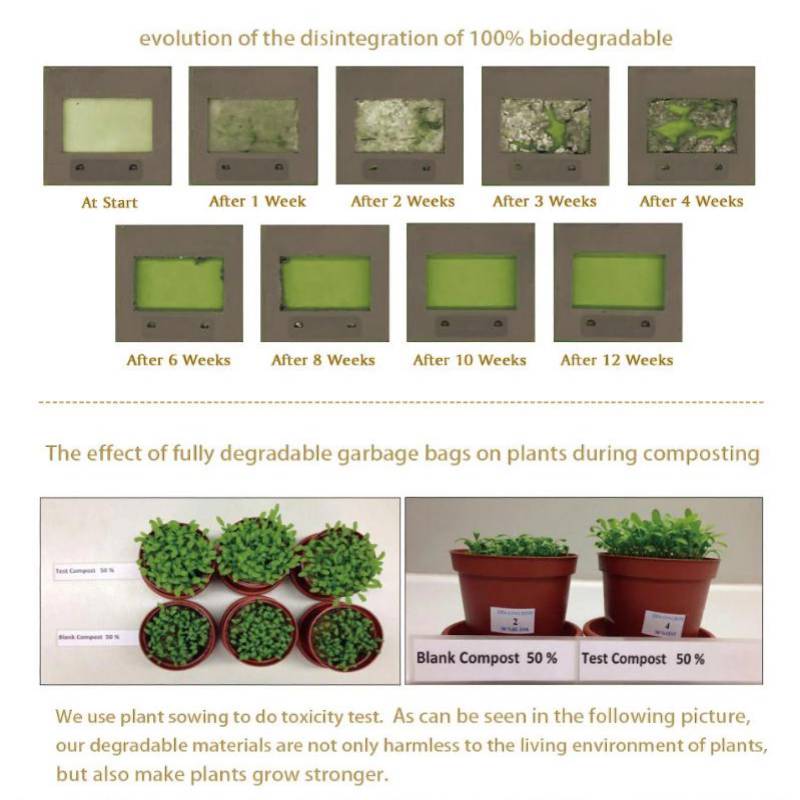

Toxicity test of residual compost. The decomposed residual soil was mixed with general soil, and the plant growth control analysis was carried out.

Regarding price issues, the price of biodegradable plastic raw materials is about 1.5 to 2 times the price of traditional plastic PE, and the price gap of finished plastic bags is about the same. Since biodegradable plastics are not the mainstream in the world, the price of raw materials is high. As more and more countries and regions implement a "comprehensive plastic ban", the amount of use in the world will increase, and the price of raw materials will also drop. .

In order to promote revolutionary changes in the environmental protection industry and eliminate white pollution, We continue to innovate based on customer needs and technological leadership, opens up cooperation with industry partners, focus on building future-oriented technology pipelines, and continues to serve customers and the whole world.

At the same time, in order to reduce costs and improve the cost-effectiveness of products, the 30,000-ton polybutylene succinate (PBS) project of Anhui Sealong Bio-based has been progressing in an orderly manner. Stay tuned.